SAFE-FIRE NEWS 2019 Q4

EVENTS

SAFE-FIRE WAS INVITED TO JOIN THE PHILIPPINES COAL PLANT USER GROUP CONFERENCE

From October 2nd to 4th, Safe-Fire Inc. was invited to join the Philippine Coal Plant User Group conference.

During the 3-day event, Safe-Fire representatives had the opportunity to discuss with end-users on issues that trouble the plant operators. The endusers were intrigued by Safe-Fire new approach

addressing CFB erosion issues. Several of the endusers have expressed their interests to further explore the product and solution Safe-Fire is offering.

PROJECT

As such, Safe-Fire has generated several solid leads and potential partnerships, both within Malaysia and ASEAN region.

SAFE-FIRE SU-2000 FLAME DETECTOR

IN OPERATION AT UNIT #3 OF NANTONG POWER PLANT, CHINA

.jpg)

Power Plant: Nantong Power Plant, China Huaneng Group

Power Output: 4x 350MW

Boiler: Opposed Fired Boiler by Babcock & Wilcox

Burner: 32 sets oil burners & 32 sets coal burners

Safe-Fire completed the retrofit of flame detection system for Nantong Power Plant, Unit #3, in China. The previous flame detection system was deteriorating with weak signals and frequent failures, which imposed great threat to the safe operation of the boiler. Safe-Fire provided a solution that best fit the site conditions as well as satisfied the end-user’s need. Using Safe-Fire’s SU-2000, the integrated flame detector unit, separate amplifiers were not required. This not only lowered the equipment cost, but also reduced problematic points.

The elimination of amplifier cabinet saved material and labor costs for onsite wiring. The project was successfully completed in December 2019.

SAFE-FIRE SA-3000 FLAME DETECTOR

SUCCESSFULLY PASSED 168 HOUR FULL LOAD OPERATION AT HUADIAN LAIZHOU POWER PLANT PHASE

POWER PLANT: Huadian Laizhou Power Plant, 4x1000MW, China

BOILER: Tangential fired Boiler by Shanghai Boiler Works LTD.

BURNER: 16 sets oil burners & 48 sets coal burners

Safe-Fire’s SA-3000 intelligent flame detection system was selected for the Phase II project of Unit #3 & #4 of Huadian Laizhou Power Plant. This is a world-class showcase smart power plant known for its ultra-low energy consumption, ultra-low emission and scenic views. The SA-3000 is a high protection class product and its temperature rating is 100°C. The system is architected to prevent explosion under the harsh detection condition. It protects the safe and stable operation of the boilers.

Unit #3 successfully completed 168-hour trial operation in August 2019.

Unit #4 successfully completed 168-hour trial operation in November 2019.

APPLICATION

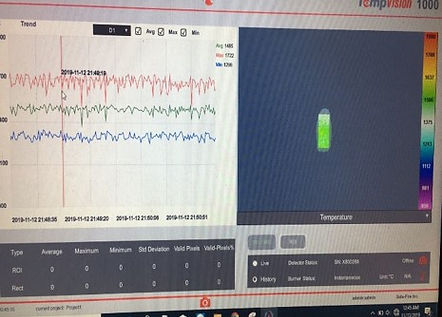

TEMPVISION 1000

Safe-Fire service team collected the temperature profile of each burner via existing viewing port located at the front wall of boiler unit 2 of Hwa Ya Power Plant. The measurement data revealed that the deviation between the min and max temperature is fairly large. Balance the temperature distribution at the same level is the key to achieve an optimized combustion for this type of boilers. Based on the temperature data, the team did a quick experimenting adjustment of some of the secondary air dampers. This alone immediately delivered a result of NOx emission reduction and efficiency improvement.

The boiler output increased by 0.6% and the NOx emission is lowered by 10.9%.

PRODUCT

EZ-FLAME FLAME SCANNER

PRODUCT OVERVIEW

The EZ-Flame Scanner is a highly sensitive and precise optical detection device which sends real-time flame quality information to the EZ-Flame Amplifier. The scanner can perform accurate flame characterization on burner flames at various stages of boiler startup and during operation. It is available in Ultra Violet,

Infra-Red, or dual UV/IR configurations. As a critical safety device, the EZ-Flame Scanners have a built-in self checking routine which confirms optical functionality every 2 minutes. In addition, and unique to Safe-Fire, each scanner sends real-time temperature readings to give its operators feedback regarding conditions at the scanner head. These features are intended to increase confidence in the flame quality measurements and overall scanner performance.

EZ-FLAME FLAME AMPLIFIER

The EZ Flame Amplifier uses an advanced DSP microprocessor and SMT technology to deliver accurate and reliable performance. Each EZ Flame amplifier can communicate with up to two separate flame scanners and can be configured to have Dual-channel IR, Dual channel UV, or Single channel IR and Single channel UV or IR and UV mixed channels from a dual sensor flame scanner. The amplifier comes equipped with 9 LED’s to function as local status indicators for power, flame, alarms, and active program files. In addition, the EZ-Flame Amplifier also has an automated self diagnostic routine which cycles every 2 minutes to confirm functionality of each flame scanner. The EZ-Flame Amplifier can store 2 user defined file parameters for each channel. This allows the user to quickly switch parameters when different fuels are used, minimizing downtime. These files can either be switched electronically by the use of our proprietary software “Rodin”, or manually via the 4 push buttons on the front of the EZ-Amplifier.

EZ-FLAME AMPLIFIER BASE

PRODUCT OVERVIEW

The EZ-Flame Base merges the EZ-Flame Scanner and Amplifier, providing the means to link with up to 128 EZ-Flame sets that will simultaneously communicate with our proprietary “Rodin” control software. In addition to the networking capabilities, each EZ-Flame Base is equipped with 29 easy access terminal slots that will relay information on flame quality, flame status, alarms/relays, self-check and temperature feedback to a DCS, PLC, or other external devices.

APPLICATION

TEMPVISION 1000

IMPROVES FUEL EFFICIENCY AND LOWERS EMISSION FOR FRONT FIRED BOILER

POWER PLANT: Hwa Ya Power Plant, Unit 2, 500 T/Hr, Taiwan

BOILER: Front-fired by FHI, Foster Wheeler license

BURNER: 8 Coal burners

TempVision 1000 captures and displays the temperature profile of each burner flame in real time. This versatile mobile device enables technicians to accurately map the profile of any burner using any available opening at any level. Through reliable and precise measurements, TempVision 1000 is the cornerstone in optimizing burner flame temperature distribution, which results in reduced fuel costs, NOx, and CO emissions.